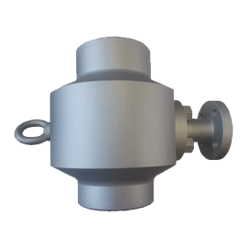

VARIvent Desuperheater

The VARIvent desuperheater is designed for effective steam temperature reduction using venturi-shaped nozzles that ensure rapid and efficient atomization of water. It is ideal for moderate load conditions and applications where accurate temperature control is essential.

The VARIvent gives you the following benefits:

- Precise temperature control

- Efficient water atomization

- Handles low-velocity steam

- Suitable for moderate load changes.

For sales or commercial inquiries please contact us at marine@insatech.com.