Enhanced Fluid Velocity Control with VARIspring DM Nozzles

VARIspring DM nozzles offer a significant advantage over fixed area nozzles by minimizing the limitations associated with reduced fluid velocity when flow rates decrease. These nozzles are designed to automatically adjust the passage area as the flow rate changes, ensuring that fluid velocity remains optimal for effective atomization.

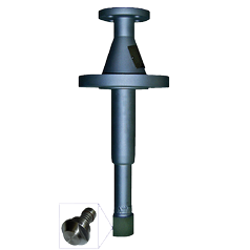

The operation of the VARIspring nozzle is based on a spring mechanism that keeps the plug in a closed position until water pressure rises sufficiently. When the pressure differential (Δp) between the steam and water increases, it eventually overcomes the spring load, allowing the plug to open. Water then flows through specially designed passages in the nozzle body, creating a swirling effect before contacting the conical surface of the plug. This design enables the nozzle to atomize water in a conical pattern effectively. Additionally, the spring load is adjustable, allowing for customization of the start opening pressure to meet specific application needs, ensuring consistent performance across varying flow conditions.