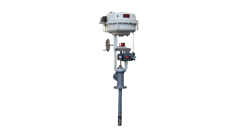

VariFrigo Desuperheater

The VariFrigo from Carraro is designed for precise liquid injection into gas streams, ideal for low-temperature desuperheating applications down to -100°C. It’s commonly used in processes like ammonia and carbon dioxide cooling, ensuring safe and efficient performance.

The VARIfrigo is giving you the following benefits:

- Operates to -100°C

- Versatile applications

- Stainless steel construction

- Heavy-duty insulation.

For sales or commercial inquiries please contact us at marine@insatech.com.