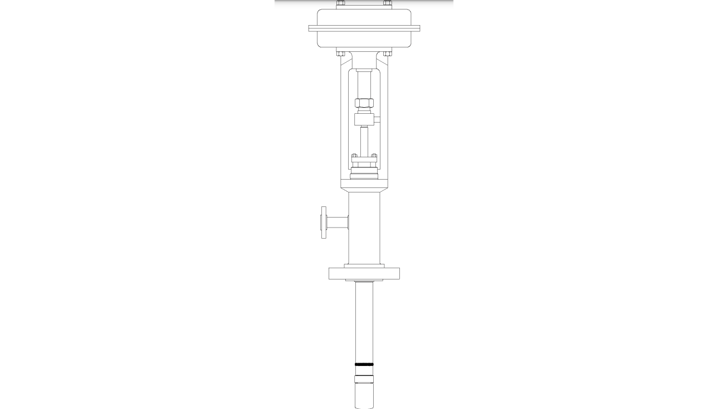

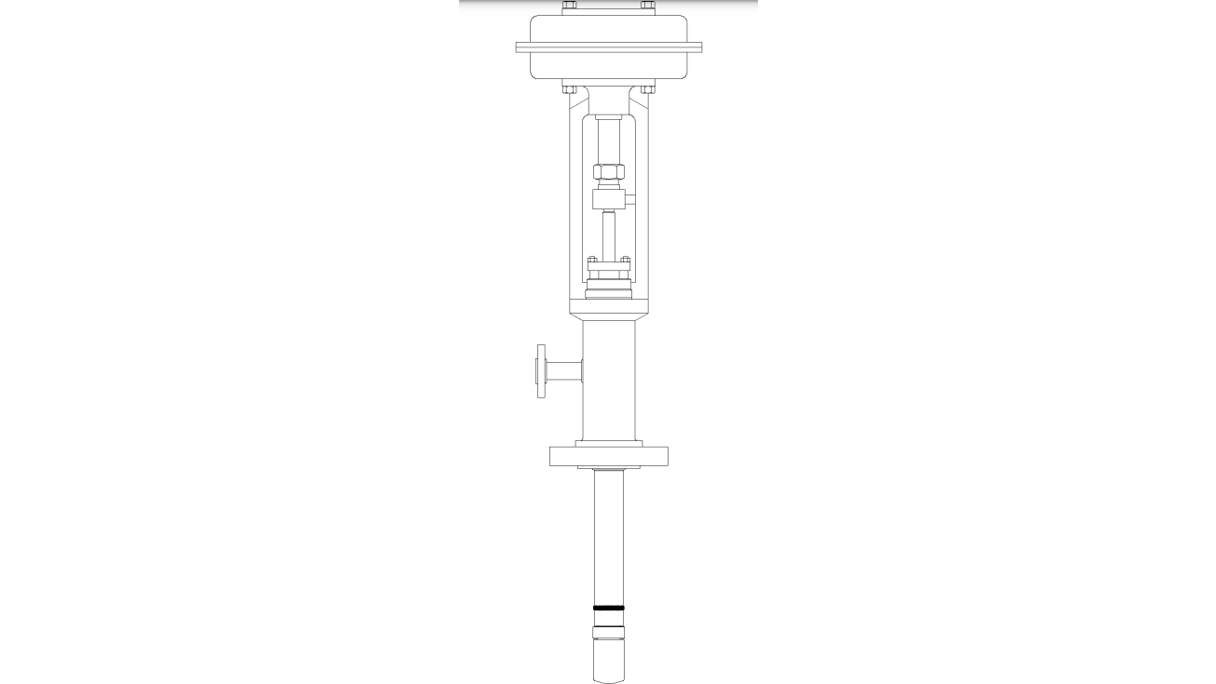

Variflow Desuperheater

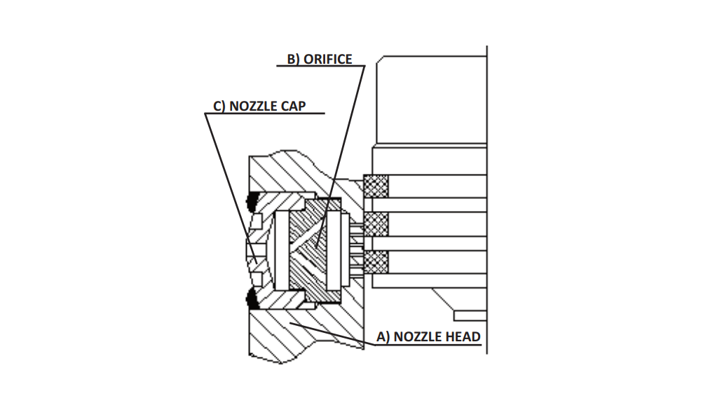

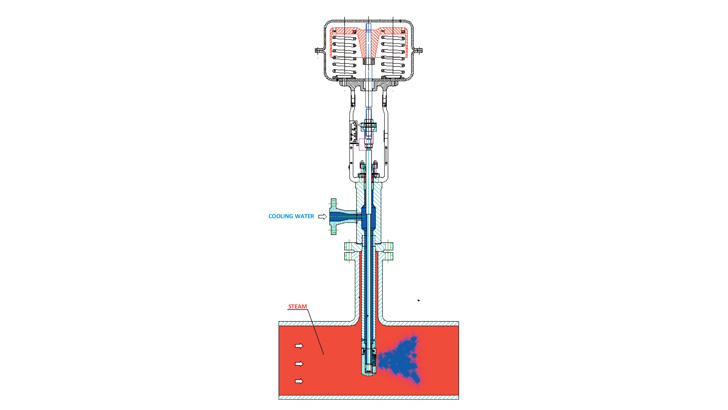

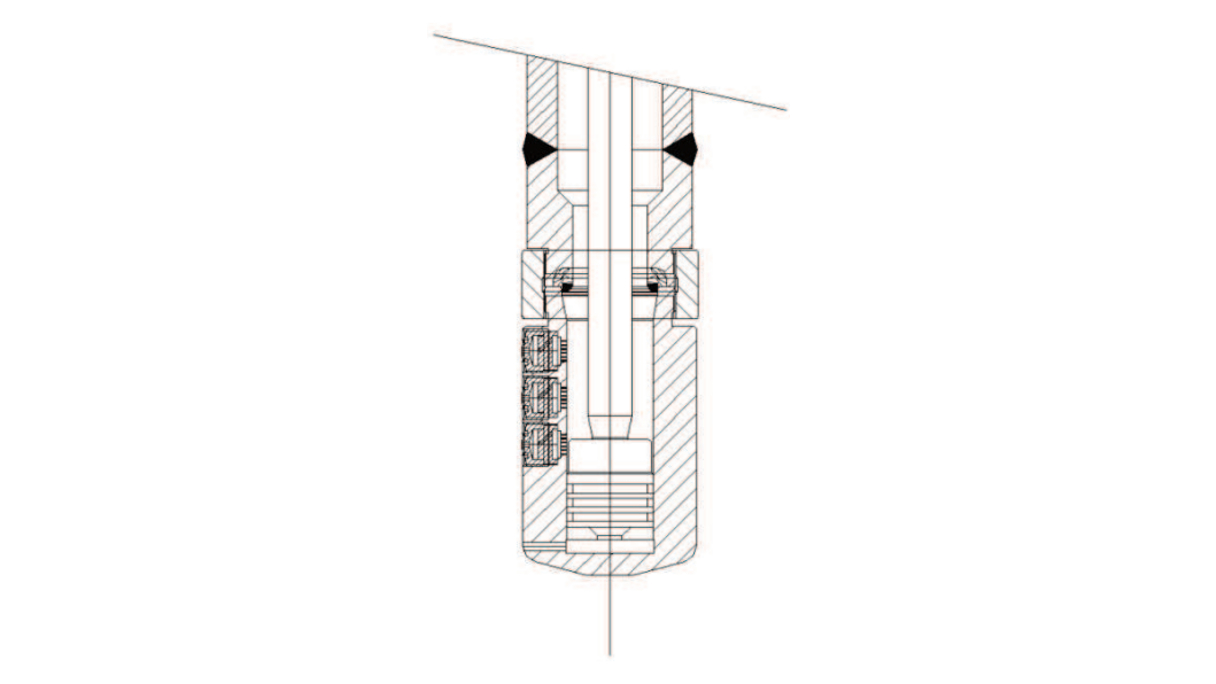

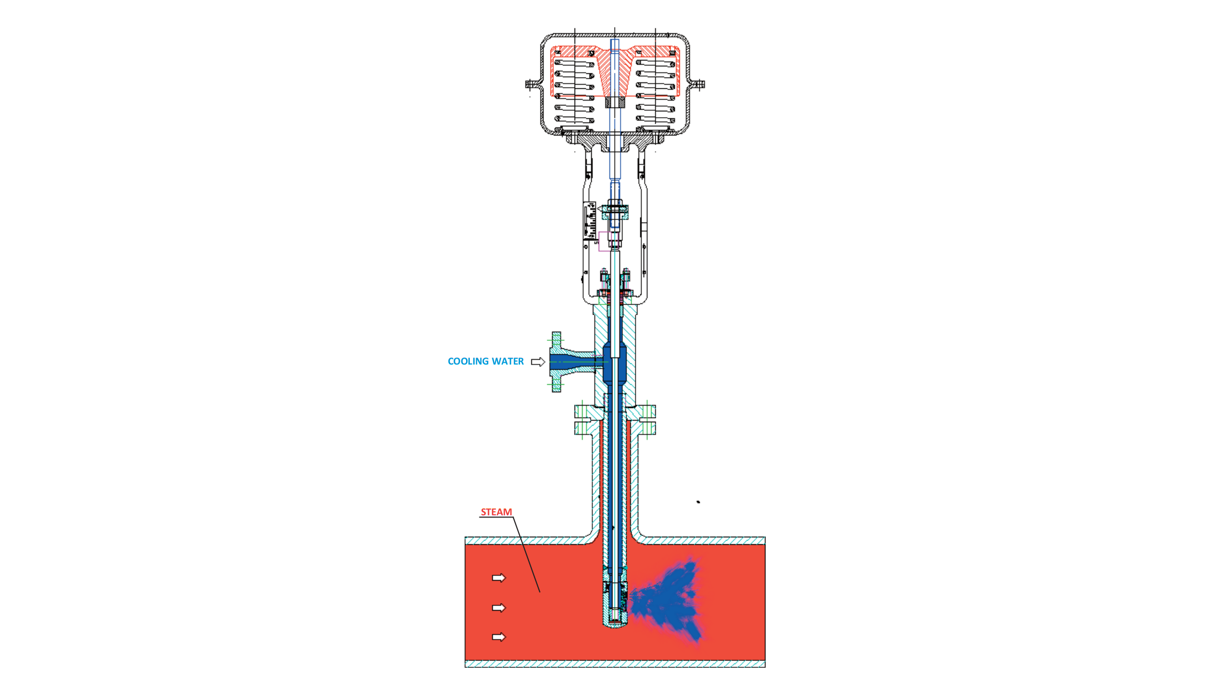

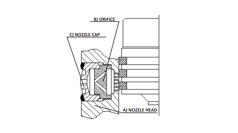

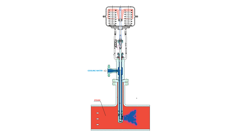

VARIflow series desuperheaters from Carraro offer an efficient solution for precise steam temperature control, providing excellent water atomization and high rangeability. They bridge the gap between simple mechanical sprays and more complex, high-performance systems, making them ideal for a wide range of applications without the need for auxiliary control valves.

This system gives you the following benefits:

- Precise temperature control

- High rangeability

- No auxiliary valve required

- Handles high pressure.

For sales or commercial inquiries please contact us at marine@insatech.com.