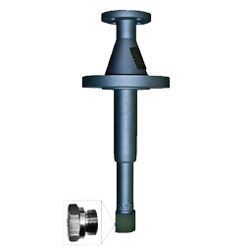

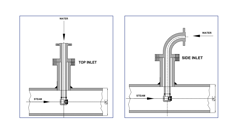

VARIfix DF Nozzle

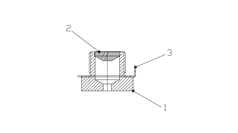

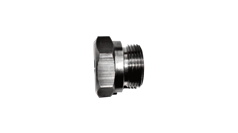

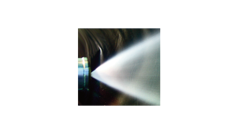

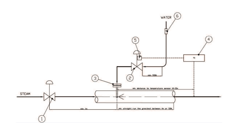

VARIfix DF nozzles from Carraro are fixed-area spraying devices designed to deliver excellent atomization with minimal water droplet size, even at low differential pressures. Ideal for applications with near-constant loads, they offer reliable performance and moderate rangeability, while minimizing water impact against internal pipe walls.

The VARIfix gives you the following benefits:

- Excellent atomization

- Small droplet size

- Handles load fluctuations

- Minimized pipe impact.

For sales or commercial inquiries please contact us at marine@insatech.com.