Valves with fixed or variable nozzles for steam conditioning / desuperheating. Vapor temperature up to 570 ° C and cryogenic media down to -150 ° C

Conditioning valves

Carraro - Desuperheater VariFlow

VariFlow series from Carraro is a multi-jet desuperheater system, designed to combine efficient water atomization with high regulating power.

Conditioning valves

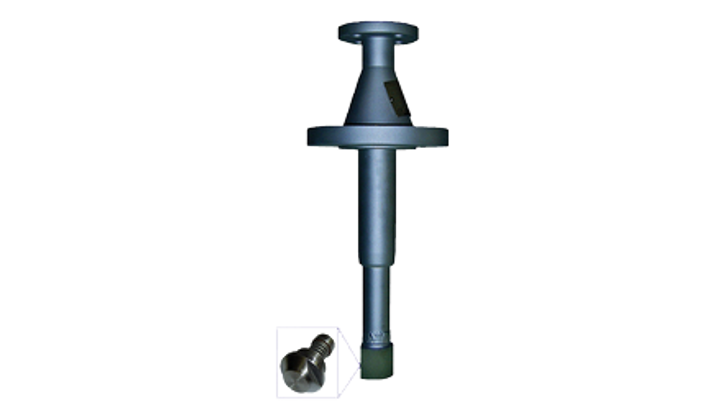

Carraro - Desuperheater VariFix

The VariFix nozzle head with 1 to 15 nozzles provides excellent sputtering in a fixed area. In each nozzle, an internal vortex ring is built in, which ensures a very small size of the water droplets also at low differential pressures.

Conditioning valves

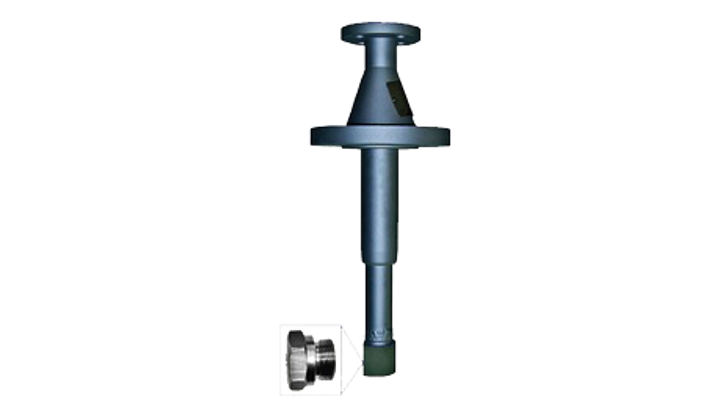

Carraro - Desuperheater VariSpring

VariSpring nozzle head has a larger process window than fixed-area nozzles and is spring-loaded.

Conditioning valves

Carraro - Desuperheater VariSpray

VariSpray is a desuperheater with fixed-area nozzles and is used for injecting water droplets into steam via a venturi-shaped section. Along with a combination with a pattern of nozzles, this ensures an excellent and rapid atomization of the injected water.

Conditioning valves

Carraro - Desuperheater VariVent

VariVent desuperheater for control and reduction of steam temperature. The venturi-shaped nozzles efficiently atomize the water and are activated by a control valve mounted before the desuperheater. They are primarily intended for moderate loads and where precise temperature control is crucial.

Conditioning valves

Carraro - Desuperheater VariBull

VariBull is a robust and compact designed valve for temperature control and temperature reduction of steam.

Conditioning valves

Carraro - Desuperheater VariFrigo

VariFrigo, variable desuperheater for areas with low temperatures. In addition to cooling the steam, Carraro's desuperheaters can also be used in many other applications where there is a need for injection of liquids into a gas stream.