High reliability with hardened materials

Standard hardened trim materials in the 41005 Series provide excellent wear resistance and long life, even

under high-pressure and high-temperature conditions. Various trim options are available to control and reduce the potentially damaging effects of noise and cavitation. Overall valve reliability is also enhanced with minimized application of soft goods such as gaskets and seals.

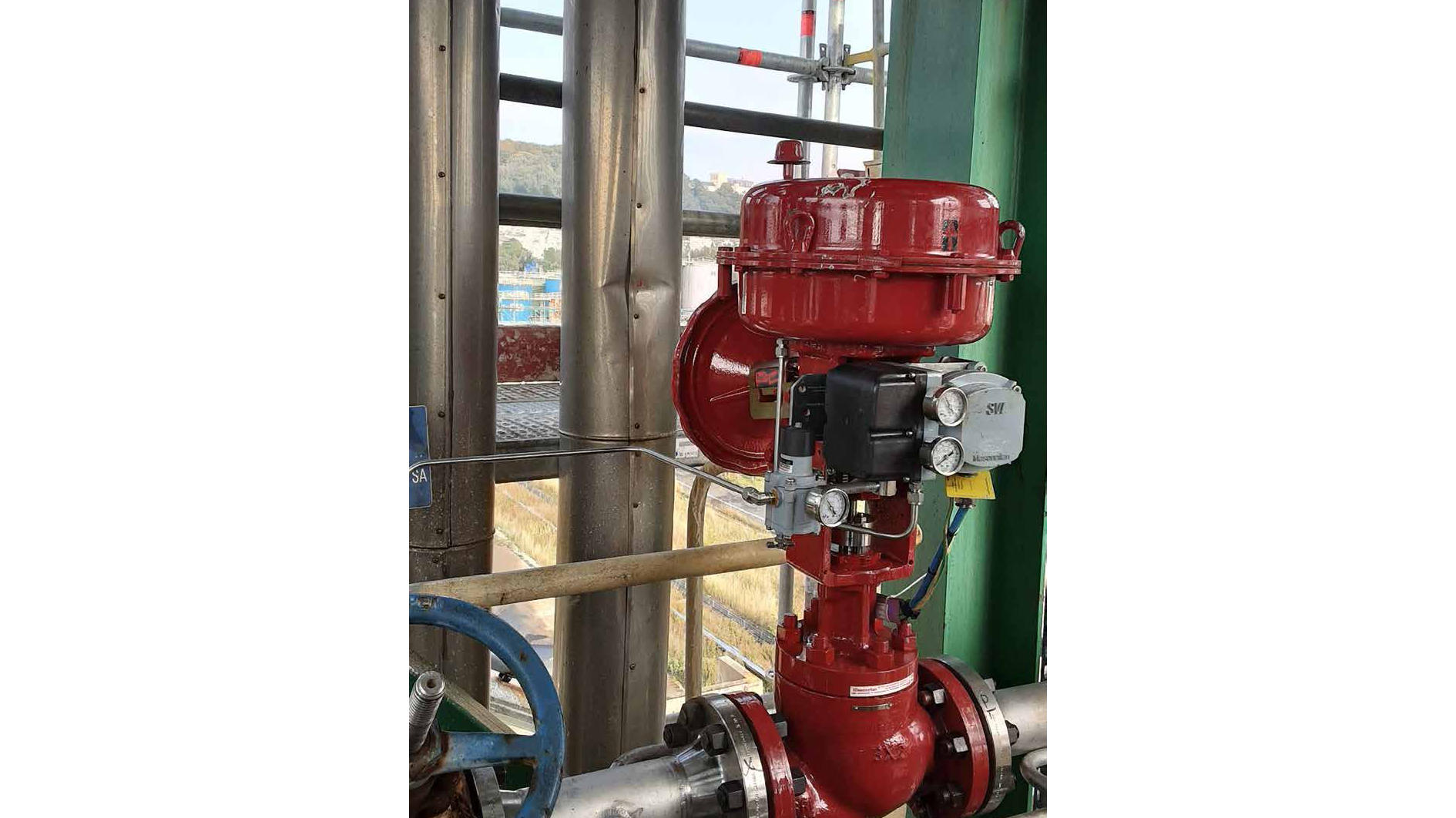

Balanced trim

A balanced trim design makes it possible to use a smaller actuator, which reduces both the physical dimensions and overall weight.

Low-emissions compliance

Addressing environmental concerns surrounding fugitive emissions from industrial plants, Baker Hughes offers low-emissions packing options for all Masoneilan globe valve designs, meeting various global and regional requirements. The EPA-compliant Masoneilan LE™ Packing design also is available in a fire- safe version.

Extended life cycle

You also have the option of anti-cavitation trim in both single-stage and double-stage configurations. It is extremely important to be able to control the dynamic cavitation conditions of the process in order for you to maintain a continuously high performance as well as reliable and accurate regulation. In addition, damage to the equipment is prevented, which prolongs the life and saves you money.

Lower operating costs

Dependable control valve tight shut-off helps minimize the loss of valuable process fluids and potentially can eliminate the need for separate isolation valves. In addition, excessive valve-seat leakage can lead to

premature trim wear and reduced performance. The 41005 Series is available with a pilot-balanced trim

option for tight shut-off (Class V) at high temperatures, and a soft-seat design for bubble-tight (Class VI) shutoff in accordance with ANSI/FCI and IEC specifications.