SIPART PS2

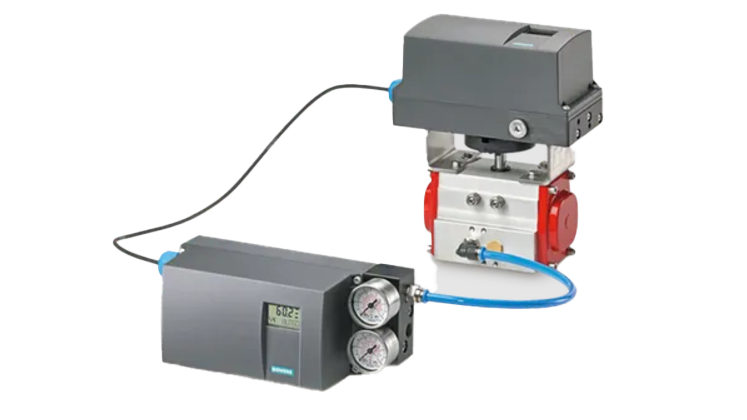

The SIPART PS2 is Siemens' advanced electropneumatic positioner designed for precise control of pneumatic valves. Offering exceptional performance and versatility, it supports single- and double-acting actuators across various industries. Its intelligent features, including diagnostic capabilities and energy-efficient operation, ensure optimal process control and reduced maintenance costs.

The PS2 gives you multiple benefits:

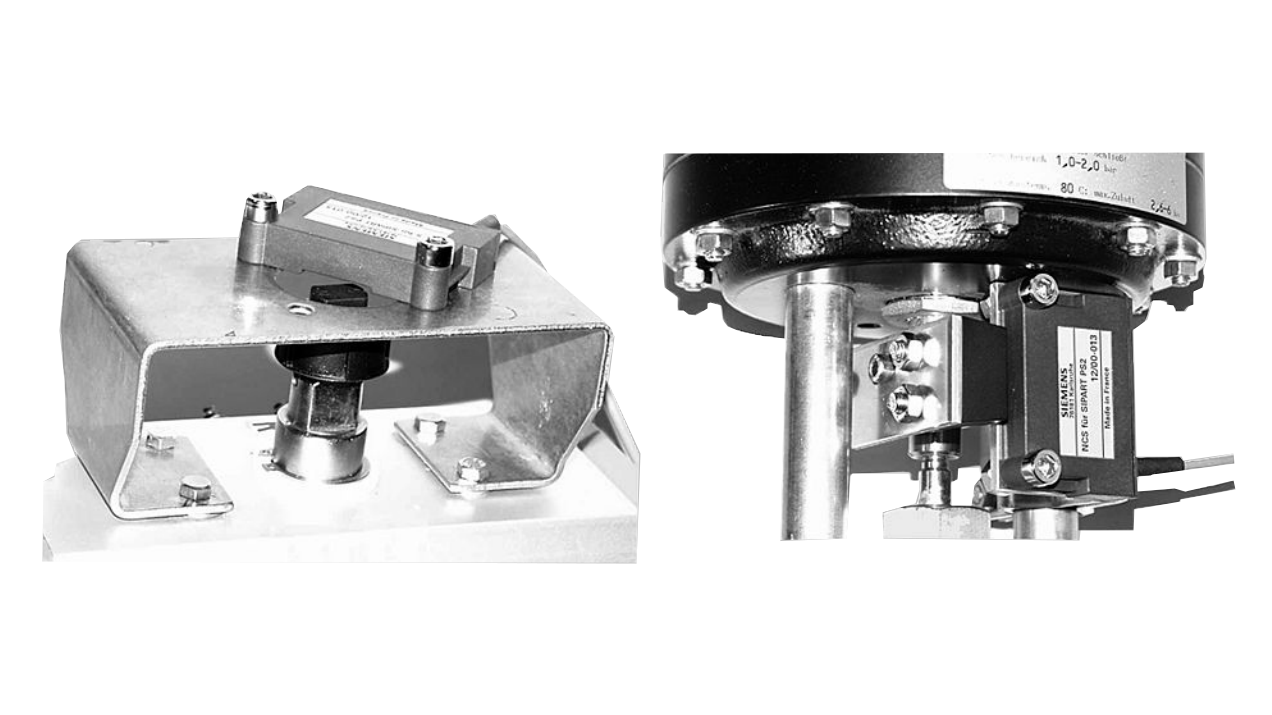

- Easy installation

- Minimal air consumption

- High control precision

- Enhanced safety functions.

For sales or commercial inquiries please contact us at marine@insatech.com.