Being able to control flow, flow rates and flow direction, is critical to many processes. Depending on process flow, pressure and media, different types of valves need to be utilized. Ball valves, needle valves, solenoid valves, butterfly valves and pressure relieve valves, are some of the more common valves used on board ships. Furthermore, most valves can be remotely operated via actuators and signals.

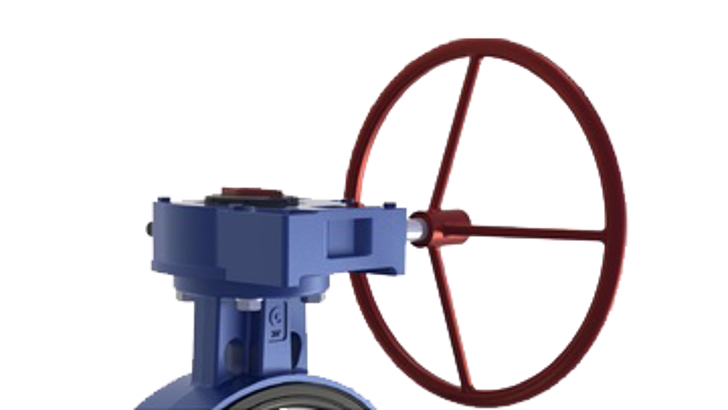

Butterfly Valve

Ghibson - Gearbox HW and AB

Ghibson's gearbox HW and AB are available in 2 different versions, model HW and model AB, and in standard sizes from DN 40 to DN 800. Other sizes on request.

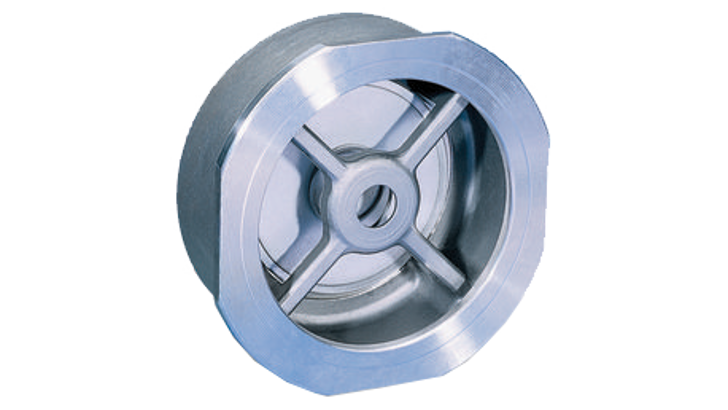

Check Valve

Ghibson - Wafer Check Valve GA015

The Wafer Check Valve GA015 from Ghibson is available in DN 15 to DN 100 - 1/2” to 4”, Pmax 52 bar. Furthermore, you can get it with a house, disc, seat plate, and spring in stainless steel and other materials on request.

Check Valve

Ghibson - Wafer check valve GB 015

Ghibson - Wafer check valve GB 015 is available in DN 15 to DN 100 - 1/2” to 4”, Pmax 52 bar. Moreover, it is small in size, low in weight and can be installed in all positions. Available with house, disc, spring, and top ring in stainless steel.

Check Valve

Ghibson - Wafer check valve GB 023

Ghibson - Wafer check valve GB 023 is available in DN 15 to DN 100 - 1/2” to 4 ”, Pmax 6 bar. Moreover, it has an opening pressure from 20 to 500 mbar. Available with house, disc, and seat in PTFE.

Check Valve

Ghibson - Wafer check valve GN 011

Ghibson - Wafer check valve GN 011 is available in DN 15 to DN 100 - 1/2 ”to 4”, Pmax 52 bar. Moreover, it is small in size, low in weight, and can be installed in all positions. Usable also as vacuum breacker, overpressure and bottom valve. Disc, spring, and seat in stainless steel and house in galvanized steel.

Check Valve

Ghibson - Wafer check valve GN 015

Ghibson - Wafer check valve GN 015 is available in DN 15 to DN 100 - 1/2 ”to 4”, Pmax 52 bar. Moreover, it is small in size, low in weight, and can be installed in all positions. Usable also as vacuum breacker, overpressure and bottom valve. House, disc, spring, and seat in stainless steel.

Check Valve

Ghibson - Wafer check valve GN 091

Ghibson - Wafer check valve GN 091 is available in DN 15 to DN 100 - 1/2 ”to 4”, Pmax 52 bar. Moreover, it is small in size, low in weight, and can be installed in all positions. Usable also as vacuum breacker, overpressure and bottom valve. House, disc, spring, and seat in hastelloy.

Previously known as GN115.

Check Valve

Ghibson - Wafer check valve GN 095

Ghibson - Wafer check valve GN 095 is available in DN 15 to DN 100 - 1/2 ”to 4”, Pmax 52 bar. Moreover, it is small in size, low in weight, and can be installed in all positions. Usable also as vacuum breacker, overpressure and bottom valve. House, disc, spring, and seat in super duplex.

Check Valve

Ghibson - Wafer check valve GT 011

Ghibson - Wafer check valve GT 011 is available in DN 15 to DN 100 - 1/2 "to 4", Pmax 160 bar. Moreover, it is small in size, low in weight, and can be installed in all positions. Usable also as vacuum breacker, overpressure and bottom valve. Available with disc, spring, and seat in stainless steel and house in galvanized steel.

No results found

Valves

Basic – but Essential to Operations

Valves are used for many purposes and are available in just as many varieties. The basic function of a valve is to create a variable barrier between the two sides of the valve. Valves are most commonly used for three purposes; open/close, control or safety. Depending on what the valves’ intended use is, the characteristics can be very different in regards to shape, size and materials.

As valves are one of the most common items found on board most ships, they are crucial for the operation, functionality and safety of the vessel. It is therefore, critical to have them functioning and well maintained at all times. If the wrong valve malfunctions at the wrong time, it could lead to delays, additional cost and in the extreme case even disaster. Apart from the valves themselves, all the directly related components are just as vital, and whether it is an actuator, a postioner or a switch, the failure of one of these ‘sub components’ could have the same affect as a failing valve.

How Can We Help?

We offer some of the most commonly used quality manufacturers of valves and supporting components in our product portfolio, and we support all of them with spares and replacements. In addition, we can be of assistance with replacement valves of alternative make and model, as well as consulting on valve solutions for new/optimized systems. We have a dedicated valve team in-house, so regardless if you are looking for spares or a complete valve we can help you.

We cover most of the valve needs you might have. Should you have a need for a specific valve type or model that is not listed, you are more than welcome to contact us, and we will do our best to help you.