Being able to control flow, flow rates and flow direction, is critical to many processes. Depending on process flow, pressure and media, different types of valves need to be utilized. Ball valves, needle valves, solenoid valves, butterfly valves and pressure relieve valves, are some of the more common valves used on board ships. Furthermore, most valves can be remotely operated via actuators and signals.

Ball Valve

Habonim - High pressure ball valve

The high pressure ball valve from Habonim is based on a floating ball valve technology, specially built for endurance and reliability with a design pressure of up to ANSI Class 2500 (414 bar / 6000 psi). As standard, the high pressure series is made from forged or rolled bar material.

Ball Valve

Habonim - Metal seated ball valves

Metal seated ball valves from Habomim excels in the harshest industrial environments, where valve failures can damage plant efficiency, reduce profitability and endanger safety. Habonim’s meticulously engineered metal seated valve can withstand the harshest applications and process conditions, including extreme high temperature, high pressure and abrasive medium.

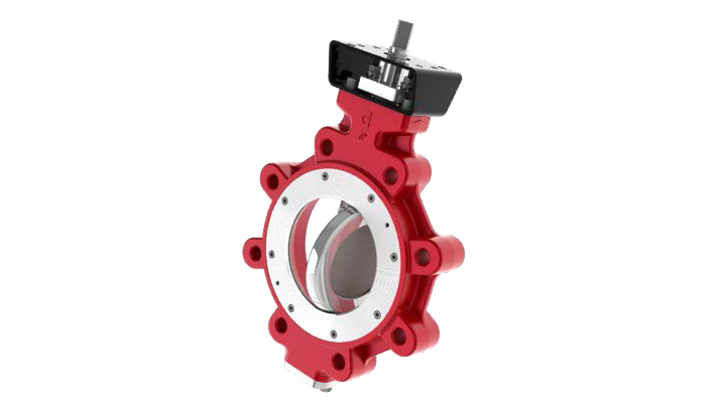

Butterfly Valve

Ghibson - Butterfly Valve HD

The butterfly valves HD-series from Ghibson are high-performance valves, which are specifically designed for high-demanding applications where the valve performance is critical. This kind of valve is available in different materials and ratings.

Butterfly Valve

Ghibson - Butterfly valve TT

Ghibson PTFE seated butterfly valves TT series are available in a wide range of materials combinations, and are specifically designed for heavy duty applications and the chemical industry.

Butterfly Valve

Ghibson - Butterfly valve PD

Soft seated butterfly valves. The PD-series is designed for low pressure (max. 6/10 bar), produced in many different materials and avalieble with wafer (BVPD) and lug (BLPD) body.

Butterfly Valve

Ghibson - Butterfly valve KI

KI-series butterfly valves from Ghibson are soft-seated valves designed for marine applications. They are available in wafer body, lug body, and double flange configurations and can also be used in vacuum environments, Maximum pressure rating of 16 bar.

Butterfly Valve

Ghibson - Butterfly valve KA

KA-Series Soft seated butterfly valves are designed to meet with most industrial and maritime applications. Manufactured with sizes from DN 40- 800, pressures up to 20 bar and many different materials. To be used also with vacuum.

Butterfly Valve

Ghibson - Butterfly valve KX

The KX-series from Ghibson, are soft seated butterfly valves engineered to meet the demands of the marine industry. Available in both wafer body and lug body designs, with sizes from DN 50-250. A wide range of material options. The valves can be used with vacuum applications and feature a vulcanized body rubber seat.

No results found

Valves

Basic – but Essential to Operations

Valves are used for many purposes and are available in just as many varieties. The basic function of a valve is to create a variable barrier between the two sides of the valve. Valves are most commonly used for three purposes; open/close, control or safety. Depending on what the valves’ intended use is, the characteristics can be very different in regards to shape, size and materials.

As valves are one of the most common items found on board most ships, they are crucial for the operation, functionality and safety of the vessel. It is therefore, critical to have them functioning and well maintained at all times. If the wrong valve malfunctions at the wrong time, it could lead to delays, additional cost and in the extreme case even disaster. Apart from the valves themselves, all the directly related components are just as vital, and whether it is an actuator, a postioner or a switch, the failure of one of these ‘sub components’ could have the same affect as a failing valve.

How Can We Help?

We offer some of the most commonly used quality manufacturers of valves and supporting components in our product portfolio, and we support all of them with spares and replacements. In addition, we can be of assistance with replacement valves of alternative make and model, as well as consulting on valve solutions for new/optimized systems. We have a dedicated valve team in-house, so regardless if you are looking for spares or a complete valve we can help you.

We cover most of the valve needs you might have. Should you have a need for a specific valve type or model that is not listed, you are more than welcome to contact us, and we will do our best to help you.