Choosing the Right SITRANS LVL Model for Your Application

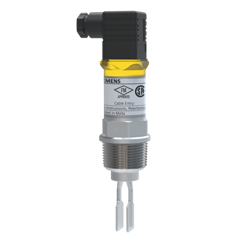

When selecting the right SITRANS LVL model, it’s important to match the features of each device to the specific application requirements. Siemens offers three distinct models, each designed for varying levels of complexity and environmental conditions, providing customers with versatile options for liquid and slurry level detection.

The SITRANS LVL100 is perfect for confined spaces, offering a very compact design with an insertion length starting at just 40 mm. It is ideal for dry-run protection and ensures reliable fault monitoring for corrosion, loss of vibration, and line break in tight spaces. This model is particularly suited for standard liquid and slurry detection where space is limited, such as small pipes and vessels.

The SITRANS LVL200, on the other hand, is built for more demanding conditions, such as detecting liquified gases with densities as low as 0.5 g/cm³. It operates efficiently in environments with large temperature variations (-40°C to 30°C) and includes enhanced safety features like fail-safe operation and SIL2 certification. The LVL200 is also designed to monitor corrosion and mechanical wear, making it ideal for harsh industrial applications with extreme pressures and temperatures.

Each model addresses different needs, allowing customers to select the best solution for their specific liquid or slurry level detection challenges.