SITRANS LVS300

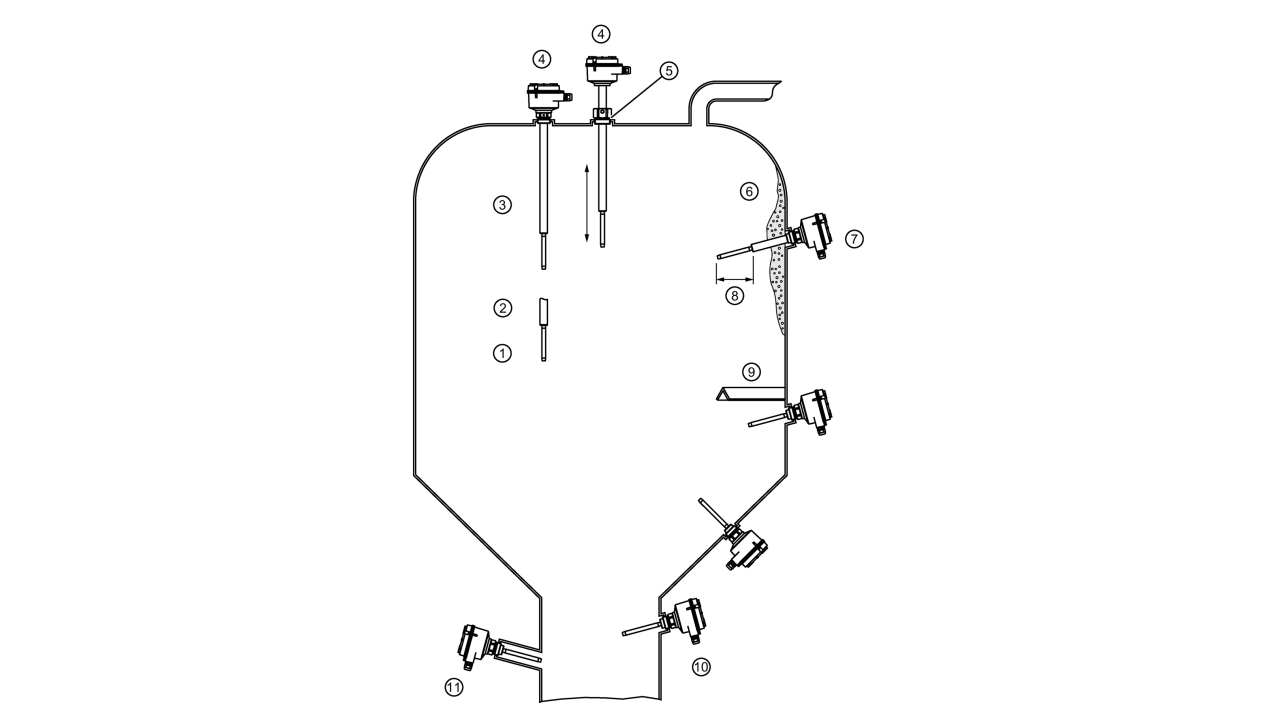

The SITRANS LVS300 from Siemens is used as a universal level switch for coarse solids and granulates. It operates at process temperatures between -40...150 °C and pressures up to 16 bar. It is available with a rod extension up to 4 m. It can be used in silos, containers, and hoppers in the cement, food, power, plastics, marine and general industries.

The LVS300 gives you several benefits:

- High mechanical resistance

- Adjustable sensitivity settings

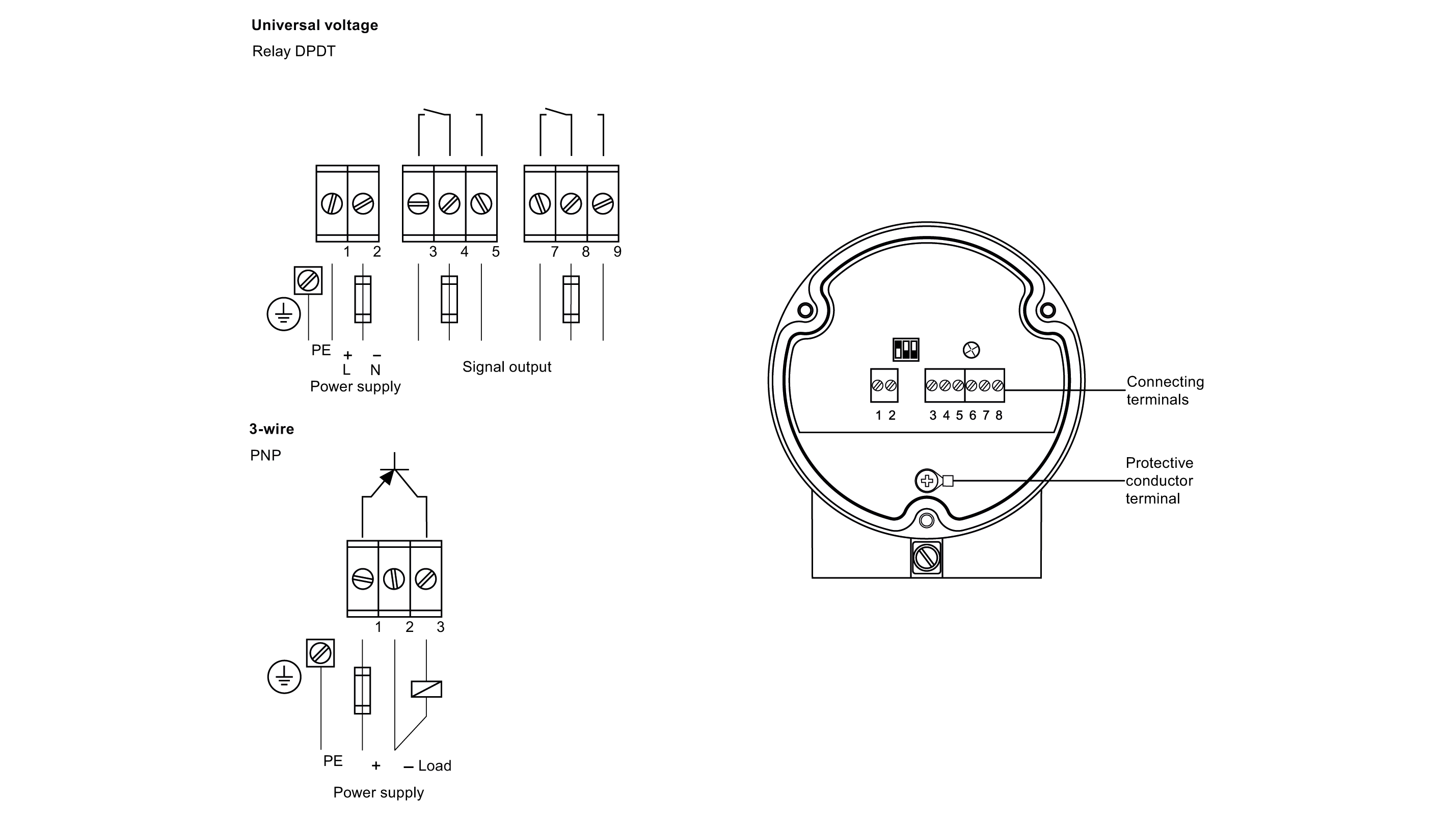

- Convenient wiring access

- Versatile mounting options.

For sales or commercial inquiries please contact us at marine@insatech.com.