SITRANS LVS200

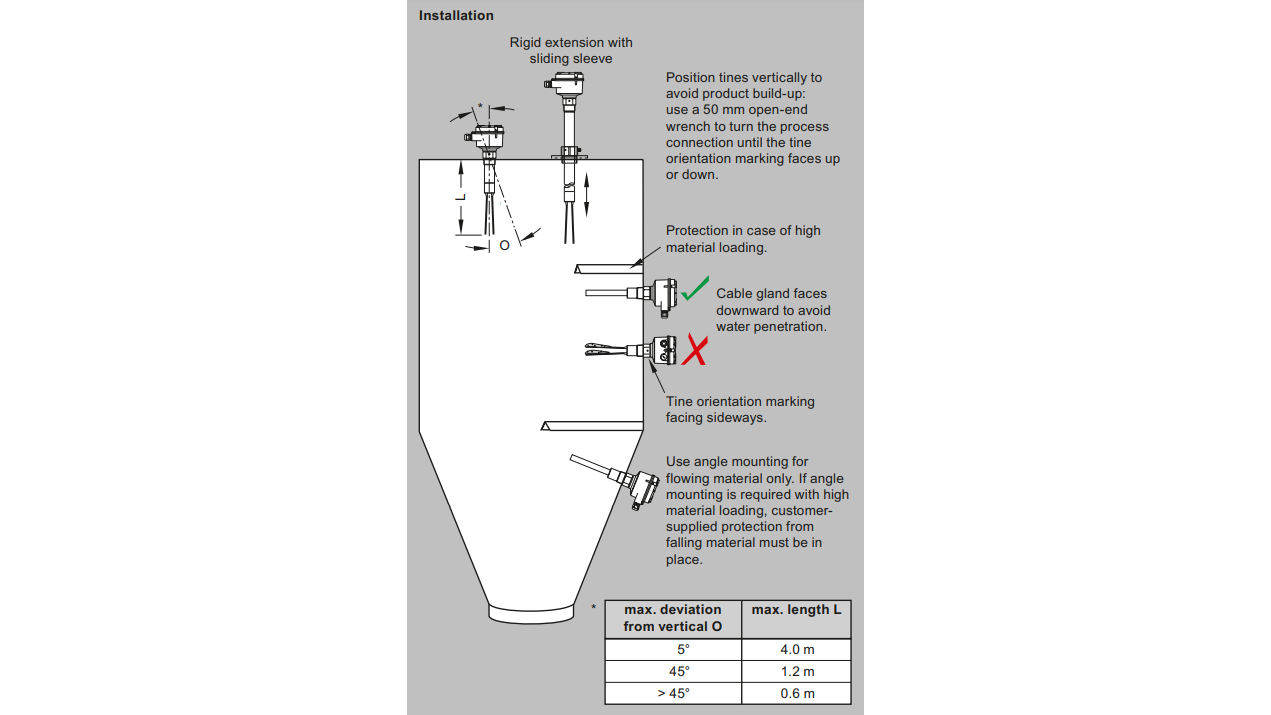

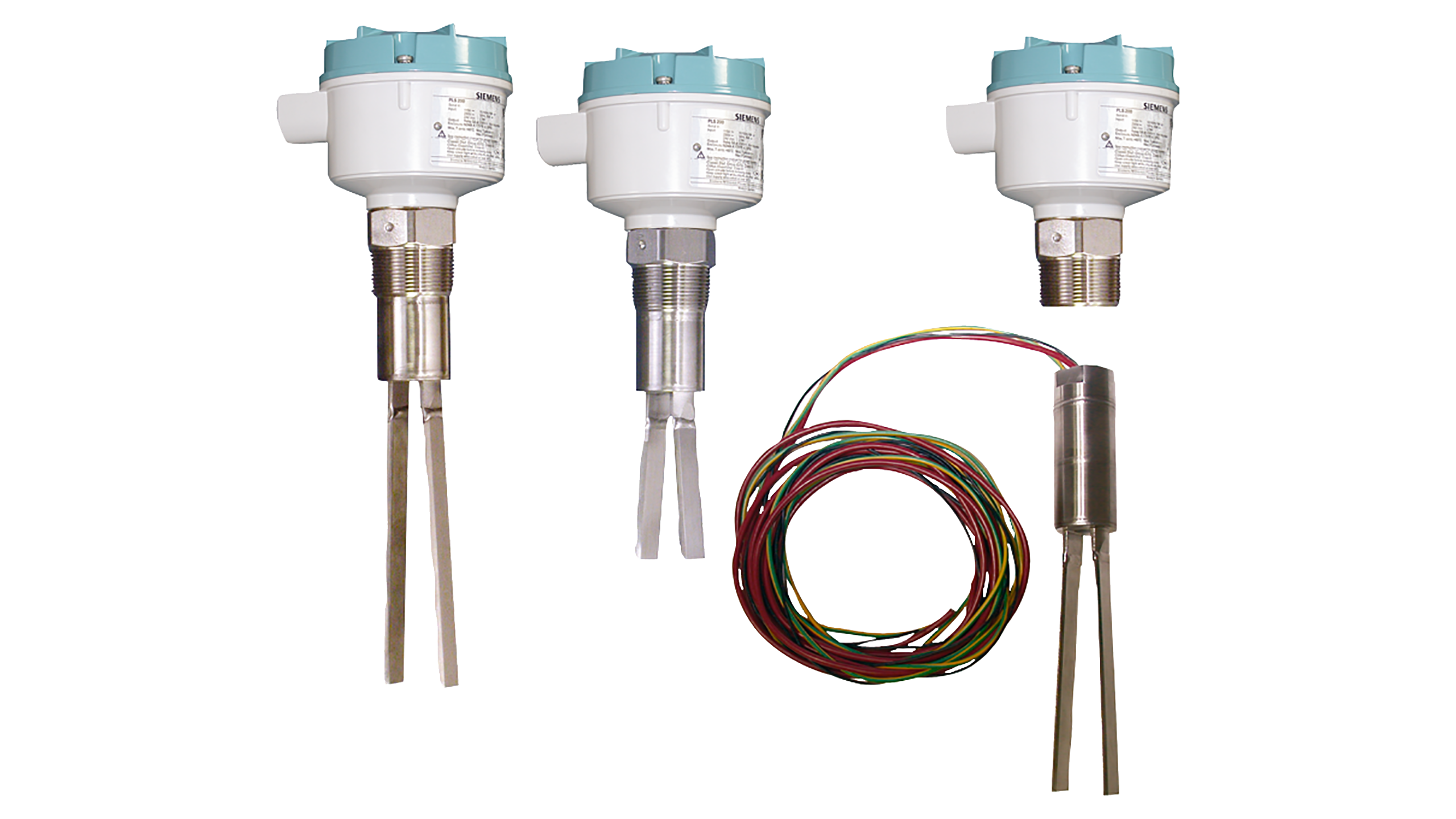

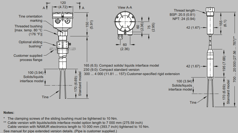

The SITRANS LVS200 from Siemens is used as a universal level switch for solids and interface measurement. It operates at process temperatures between -40...150 °C and pressures up to 10 bar. It is available with rod or cable extensions up to 4 and 20 meters, respectively.

The LVS200 gives you several benefits:

- Reliable material detection

- Easy installation and maintenance

- Handles low-density materials

- Durable under high loads.

For sales or commercial inquiries please contact us at marine@insatech.com.