SITRANS LVS100

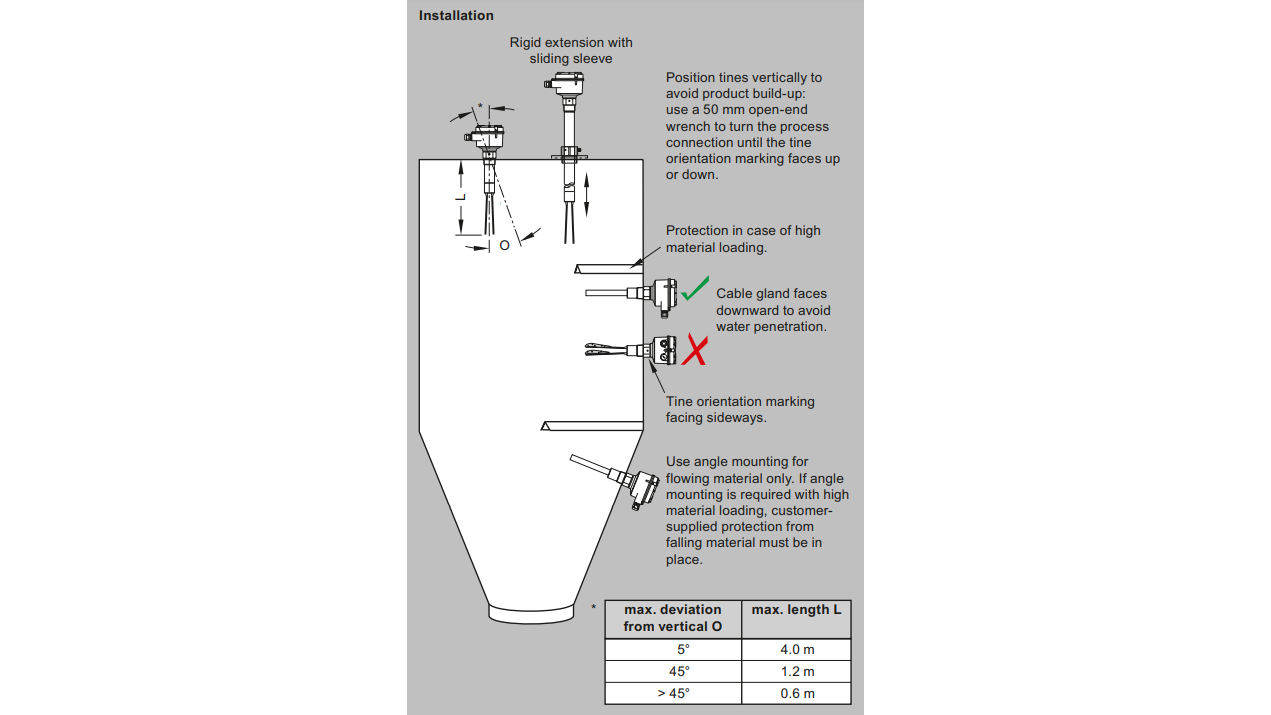

The SITRANS LVS100 from Siemens is used as a universal level switch in solids. Regardless of the mounting position, the compact switch reliably detects the limit level. It operates at process temperatures between -40...150°C and at pressures up to 10 bar.

The LVS100 gives you several benefits:

- Reliable limit detection

- Compact and versatile

- Easy installation and maintenance

- Resists false readings.

For sales or commercial inquiries please contact us at marine@insatech.com.