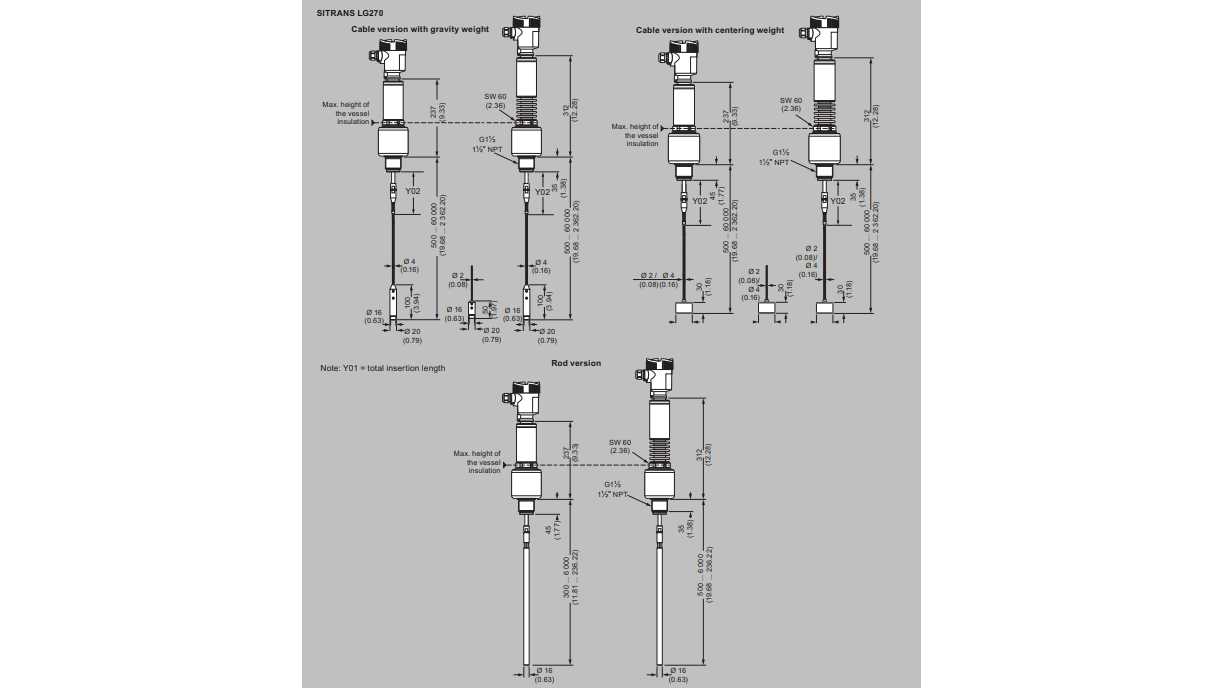

SITRANS LG270

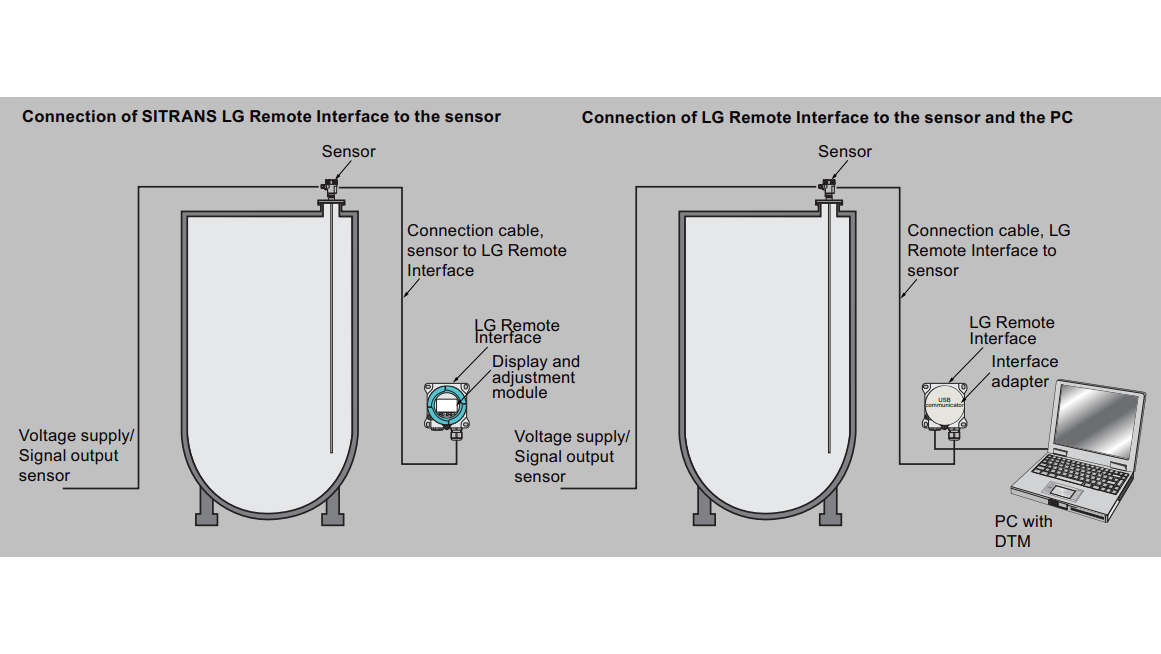

The SITRANS LG270 from Siemens is a radar particularly well-suited for level and interface measurement of liquids under extreme conditions in the chemical, petrochemical, power, general and maritime industries. It can be used for aggressive media in tanks with agitators, vapors, high temperature, high pressure, and low dielectric constant. The LG270 can measure up to 60 m, at temperatures between -196...+450 °C and up to 400 bar.

The LG270 give you several benefits:

- Extreme temperature/pressure resistant

- Handles aggressive media

- Reliable in foam/condensation

- Accurate interface measurement.

For sales or commercial inquiries please contact us at marine@insatech.com.