SITRANS LG250

The SITRANS LG250 from Siemens is a radar particularly well-suited for level and interface measurement in the chemical, petrochemical, power, and general industries. It is a flexible solution that can be used in tanks, media separation, and ammonia applications.

The LG250 gives you several benefits:

- High Accuracy

- Flexible Applications

- Robust Performance

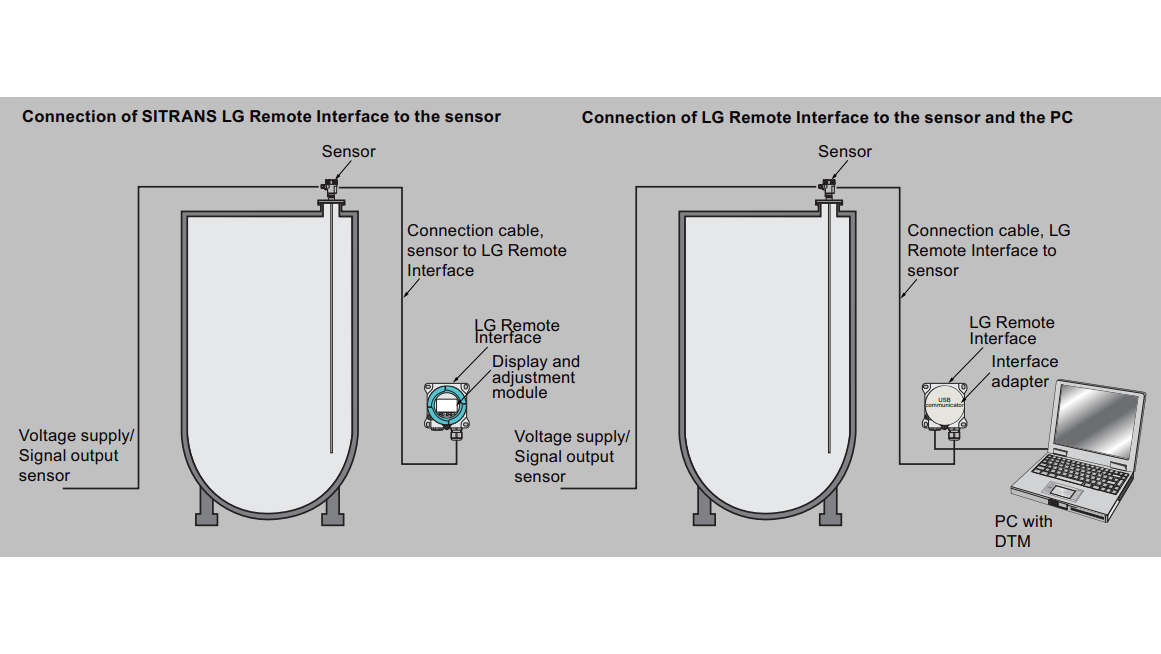

- User-Friendly Interface.

For sales or commercial inquiries please contact us at marine@insatech.com.