Here we can provide you with all calibration solutions such as (Temperature, Pressure, Weight …..etc) . Aslo we have the Torque measurement system to prevent your ship from breakdown cost. The flowmeters and vibrations sensors are very important to provide you with accurate measuring .

Pressure transmitter

DPT 200

The differential pressure transmitter DPT 200 from BD Sensors is designed to measure level in closed, pressurized tanks, pump or filter controlling, etc. The transmitter has various pressure seals available, as well as a variety of membrane materials, which makes the DPT 200 reach an optimal adaption to many applications.

Pressure transmitter

DMD 331

The DMD 331 from BD Sensors is a differential pressure transmitter, which is based on a piezoresistive stainless steel sensor. This sensor can be pressurized on both sides with fluids or gases compatible with SST 1.4404 and 1.4435.

Pressure transmitter

DMD 831

The DMD 831 from BD Sensors is a differential pressure transmitter, which is based on a stainless steel sensor.

Pressure transmitter

DMD 341

The DMD 341 from BD Sensors is a differential pressure transmitter, which is suited for the marine industry and machine and plant engineering because of its compact and vigorous aluminum housing.

Pressure transmitter

DPS 300

The DPS 300 from BD Sensors is a pressure transmitter that is developed to measure differential pressure for both dry and non-aggressive gases, as well as compressed air. Moreover, the DPS 300 is a multi-range transmitter with up to three adjustable ranges.

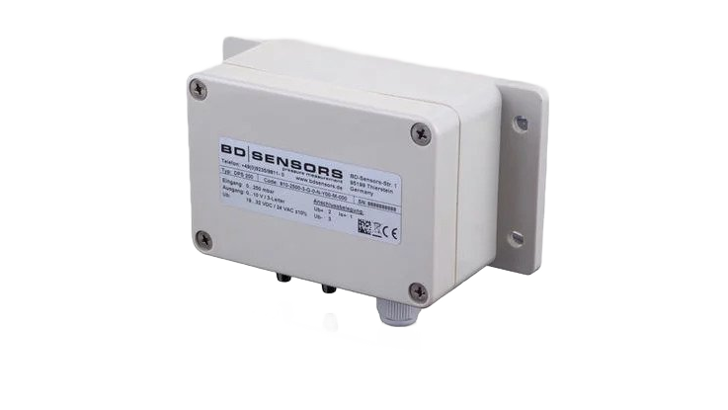

Pressure transmitter

DPS 200

The DPS 200 from BD Sensors is a differential pressure transmitter, which is applicable for gas and compressed air. The transmitter can be used in various settings and for HVAC applications.

Pressure calibrators

Additel ADT680 Digital Pressure Gauge

Additel ADT680 is an advanced digital pressure reference, with ADT680W having additional data logging and wireless communication, provides new possibilities for the use and execution of your pressure measurements. The Additel ADT680 / ADT680W series of digital pressure references covers the pressure range from -1...4200 bar(g).

Pressure calibrators

Additel ADT681 Digital Pressure Gauge

Additel ADT681 / ADT681IS is an advanced digital pressure gauge that makes it possible for you to perform pressure measurements and calibration tasks in demanding environments. You can choose Additel ADT681IS for tasks in environments that require intrinsically safe equipment. Additel ADT681IS is also IP67 rated, which means that the equipment is suitable for use in dusty and wet environments. Additel ADT681 series of digital pressure gauges that cover the pressure range from ± 2.5 mbar to 4200 bar, which makes it easy for you to find a unit that matches your accuracy and range requirements.

No results found

Marine Instruments

The importance of using proper instrumentation Electrical and mechanical instrumentation invovles design, control and implementation of devices that can measure physical quantities. There is a huge amount of thought behind the proper instrument and installation choices for each small or larger measuring point. All vessels generally use state of the art instrumentation and equipment to manage everything from the engines, steering and navigation system. When the equipment malfunctions it can have a huge impact on the operational efficiency and can cause massive downtime that can put the vessel behind schedule. A broken viscoity sensor can cause wrong engine combustion, wrong additive dosing can reduce fuel efficency or worse; lubrication properties of various lubration oils. A ballast that isnt filled appropriately after loading can impact vessel stability and leaks and dangerous pressure levels in fuel tanks can impact enginre operation or even lead to disaster.

Proper Use of the Correct Instrumentation Is Important

– a Sensor Is Not Just a Sensor

Today’s fleet is generally becoming highly sophisticated operations with equally sophisticated equipment on board. And controlling all this sophisticated equipment correctly and preventing breakdowns is crucial to a smooth and cost-effective operation. Choosing the correct instrument for measuring the processes on board is not only a good idea seen from a practical aspect, but investing the time and possibly a little extra money on instrumentation that is ideal for the task, can ultimately save the vessel both cost and unnecessary interference for the crew on board.

Measurements are used all over the modern ship in order to keep equipment running at optimum conditions. Everything from critical installations such as main engines, auxiliary engines, steering and navigation to other installations such as cranes, cargo pumps and wastewater handling can and should be monitored with optimization in mind. Optimization of processes on board a ship can contribute to better earnings and lower emissions – even if the realized optimization is only constituted by fewer unplanned interruptions such as maintenance works and breakdowns.

A malfunctioning viscosity sensor can cause lower exploitation of the fuel due to wrongful combustion; a hydraulic failure on a crane can cause delay in port operations and interrupt the planned schedule; incorrect ballast control can impact vessel stability and trim causing anything from slightly lower performance to accidents and undetected leaks in cargo and fuel tanks can cause dangerous situations or even lead to disaster.

Choosing the correct instrument for a specific task can be challenging, as a myriad of variations of a single instrument often exist. And just going by the most expensive option or for something that has been recommended, is not always the right way, as the process and media in which the instrument should be installed is what determines what measurement principle and setup should be chosen. Degradation is caused very differently based on what the instrument is exposed to, and one instrument suited for one place on board might be unsuitable for another; a different pressure might cause inaccurate reading or mechanical failure and a different media could do the same.

Across the specialists at Insatech, we have the knowledge and experience to find the right instrument for your specific application as well as we can guide you to install it correctly. Making your operation as smooth and efficient as possible is always our goal with our counselling and services, as your success leads to our success!