Here we can provide you with all calibration solutions such as (Temperature, Pressure, Weight …..etc) . Aslo we have the Torque measurement system to prevent your ship from breakdown cost. The flowmeters and vibrations sensors are very important to provide you with accurate measuring .

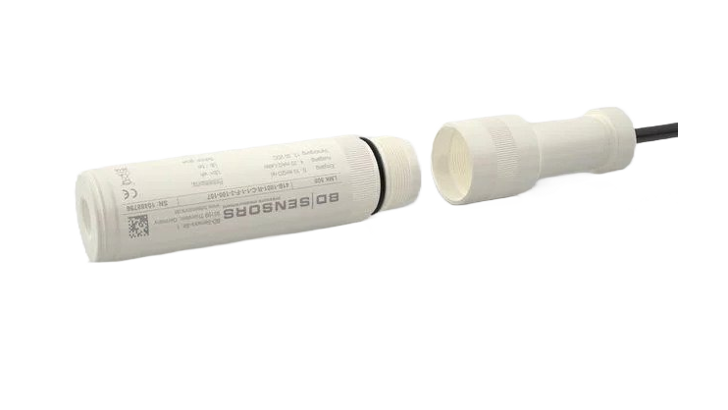

Level Probe

LMK 808

The LMK 808 from BD Sensors is a detachable plastic submersible probe, which is developed to measure level in water and wastewater. The capacitive ceramic sensor is the basis of the probe and makes the LMK 808 extremely vigorous and almost maintenance-free.

Level Probe

LMK 809

The LMK 809 from BD Sensors is a plastic submersible probe, which is designed to measure level continuously in wastewater or in various kinds of aggressive media. The basic element of the probe is the flush mounted capacitive ceramic sensor that is making it easier to clean.

Level Probe

LMK 858

The LMK 858 from BD Sensors is a separable plastic immersion probe, which is designed to measure level in aggressive media like acids and alkalis), desalination plants, and for use in more viscous media such as sludge.

Moreover, the probe’s head can be separated from the cable part, which both reduces maintenance or service tasks, as well as it simplifies storage.

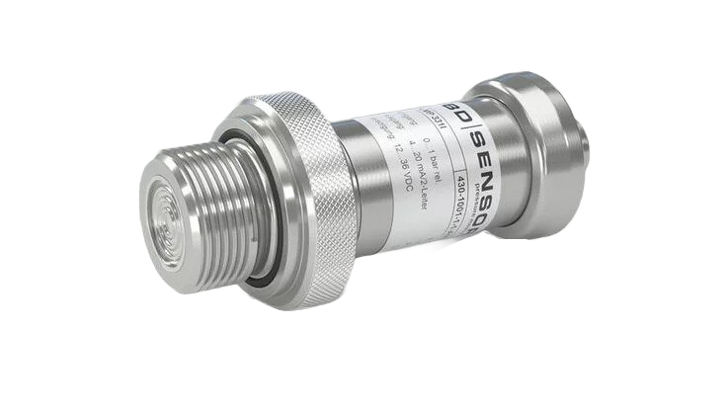

Level transmitter

LMP 331i

The LMP 331i from BD Sensors is a precision screw-in transmitter where the signal processing is done with a 16-bit analog digital converter. Consequently, you can conduct an active compensation.

Moreover, the transmitter is exceptional in measuring and is cost-effective.

Level transmitter

LMP 331

The LMP 331 from BD Sensors is a screw-in transmitter, which is designed to measure level continuously. Moreover, the modular construction of the transmitter gives you a high degree of flexibility, when adapting it to your application. This is a transmitter that also gives you exceptional performance and vigorous construction

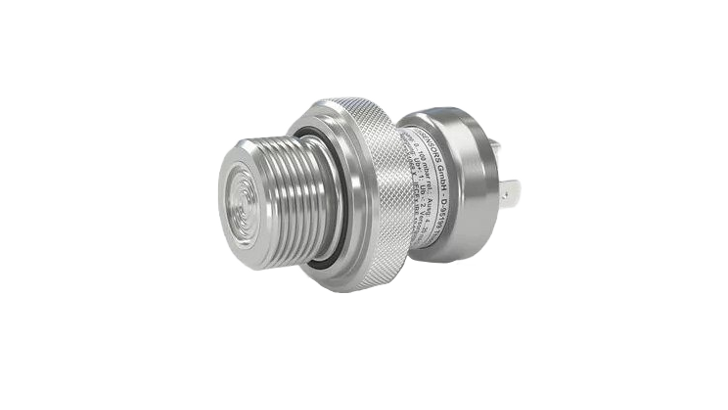

Level transmitter

LMK 331

The LMK 331 is a screw-in transmitter from BD Sensors, which has been designed to measure level and process. It is applicable to measure also pressure of liquids, oils, and gases. Furthermore, the semi-flush pressure sensor makes it possible to also use the LMK 331 in more viscous or polluted media.

Level transmitter

LMK 351

The screw-in transmitter LMK 351 from BD Sensors is designed to measure level and pressure in small systems and in containers. Moreover, the transmitter is based on the capacitive ceramic sensor element.

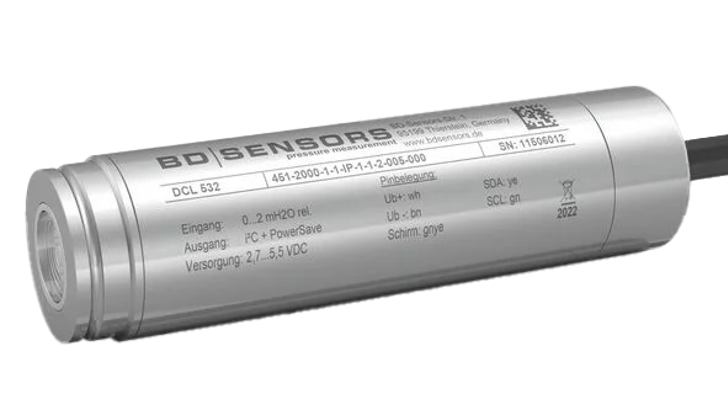

Level Probe

DCL 532

The DCL 532 from BD Sensors is a stainless-steel submersible probe with digital i²C-interface. Moreover, the probe’s basic element is a stainless-steel sensor of great quality that meet the highest requirements for accurate measurement with exceptional long-term stability.

Ultrasound liquids and solids

Siemens Echomax XPS Ultrasonic Transducer

The Echomax XPS transducers use ultrasonic technology to measure the level in a wide range of liquids and solids. The transducers can be fully submerged, are resistant to steam and corrosive chemicals, and can be installed without flanges.

No results found

Marine Instruments

The importance of using proper instrumentation Electrical and mechanical instrumentation invovles design, control and implementation of devices that can measure physical quantities. There is a huge amount of thought behind the proper instrument and installation choices for each small or larger measuring point. All vessels generally use state of the art instrumentation and equipment to manage everything from the engines, steering and navigation system. When the equipment malfunctions it can have a huge impact on the operational efficiency and can cause massive downtime that can put the vessel behind schedule. A broken viscoity sensor can cause wrong engine combustion, wrong additive dosing can reduce fuel efficency or worse; lubrication properties of various lubration oils. A ballast that isnt filled appropriately after loading can impact vessel stability and leaks and dangerous pressure levels in fuel tanks can impact enginre operation or even lead to disaster.

Proper Use of the Correct Instrumentation Is Important

– a Sensor Is Not Just a Sensor

Today’s fleet is generally becoming highly sophisticated operations with equally sophisticated equipment on board. And controlling all this sophisticated equipment correctly and preventing breakdowns is crucial to a smooth and cost-effective operation. Choosing the correct instrument for measuring the processes on board is not only a good idea seen from a practical aspect, but investing the time and possibly a little extra money on instrumentation that is ideal for the task, can ultimately save the vessel both cost and unnecessary interference for the crew on board.

Measurements are used all over the modern ship in order to keep equipment running at optimum conditions. Everything from critical installations such as main engines, auxiliary engines, steering and navigation to other installations such as cranes, cargo pumps and wastewater handling can and should be monitored with optimization in mind. Optimization of processes on board a ship can contribute to better earnings and lower emissions – even if the realized optimization is only constituted by fewer unplanned interruptions such as maintenance works and breakdowns.

A malfunctioning viscosity sensor can cause lower exploitation of the fuel due to wrongful combustion; a hydraulic failure on a crane can cause delay in port operations and interrupt the planned schedule; incorrect ballast control can impact vessel stability and trim causing anything from slightly lower performance to accidents and undetected leaks in cargo and fuel tanks can cause dangerous situations or even lead to disaster.

Choosing the correct instrument for a specific task can be challenging, as a myriad of variations of a single instrument often exist. And just going by the most expensive option or for something that has been recommended, is not always the right way, as the process and media in which the instrument should be installed is what determines what measurement principle and setup should be chosen. Degradation is caused very differently based on what the instrument is exposed to, and one instrument suited for one place on board might be unsuitable for another; a different pressure might cause inaccurate reading or mechanical failure and a different media could do the same.

Across the specialists at Insatech, we have the knowledge and experience to find the right instrument for your specific application as well as we can guide you to install it correctly. Making your operation as smooth and efficient as possible is always our goal with our counselling and services, as your success leads to our success!