Medium Capacity High Pressure Oval Gear Meters (OM Series)

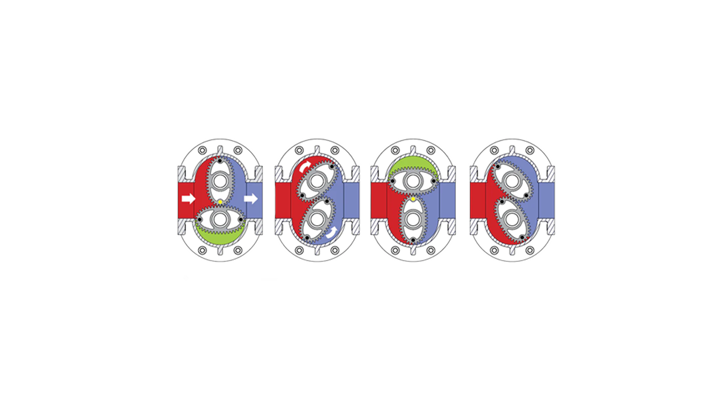

The Medium High Pressure Oval Gear Meters from FLOMEC, is part of the OM-series, and offer the ability to handle a wide range of fluid viscosities because of the increased flow range and give you an exceptional level of repeatability. This high pressure model provide volumetris measurement of clean liquids for high pressure. The medium sized meter is primarily used on medium sized vessels for diesel consumption measurement.

More advantages:

- Direct volumetric reading, which gives high accuracy and repeatability

- Measures liquids both of high and low viscosity

- No requirements for flow conditioning

- Optional Exd I/IIB approval (ATEX, IECEx)

- High pressure rated up to 400 bar (5580 psi)

We deliver directly and globally to end-users, agents, and resellers.

Contact us at quotes@insatech.com.