Condition monitoring instruments can, at a very early stage, help identify issues, that might lead to catastrophic failure. Since the monitored machinery does not require the crew’s attention, they can instead focus on more important tasks. In addition to freeing up the crew’s time, applying condition monitoring can also provide valuable information on operation and periodical maintenance optimization.

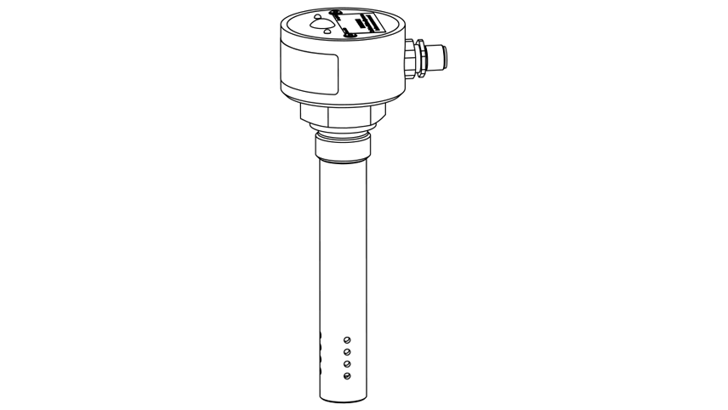

EESIFLO EASZ-2 online water in oil / fuel analyser

EASZ-2 is an online water in oil / fuel analyser that continuously monitors the water content in oil and fuel. The monitoring can help you catch water contamination, which can help prevent equipment malfunction, corrosion, component wear and more. The analyser gives you a visual indication of water content and has backlights for alarm limits / conditions (green, amber and red).

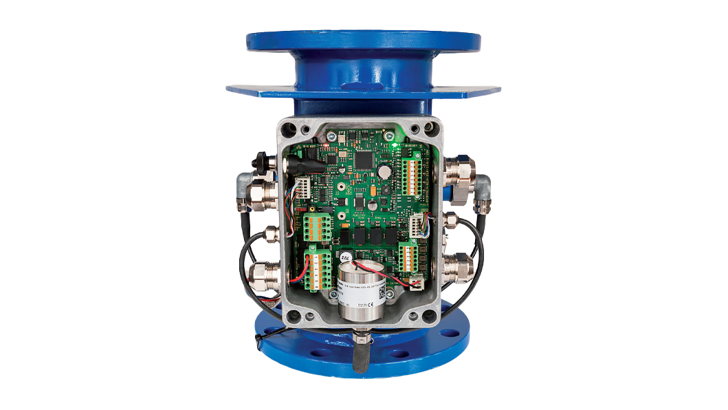

MEV283 Series

Dr. E. Horn Oil Mist Detector MEV283

The Oil Mist Detector from Dr. E. Horn is a compact system, which can detect even the smallest changes in the oil concentration and is connected to the vessel’s automation security system. Moreover, this system can be retrofitted and mounted directly on the pipes for crankcase ventilation. Thus, no additional pipping is required in the assembly.

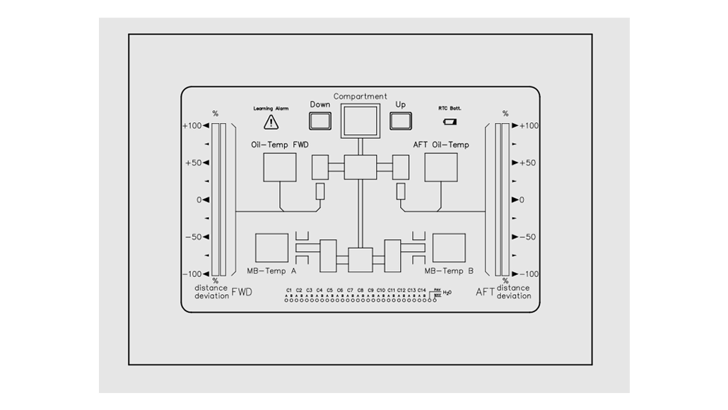

BDMS

Dr. E. Horn Bearing Distance and Temperature Monitoring System

The Bearing Monitoring System from Dr. E. Horn makes continuous surveillance of your engine in relation to the distance between the sensor and the cross hear in its lower dead point position, which is a measure of the bearing wear. One of the key benefits of the 2-stroke bearing monitoring system is improved reliability. By detecting potential issues early, operators can take proactive measures to prevent failures and minimize downtime.

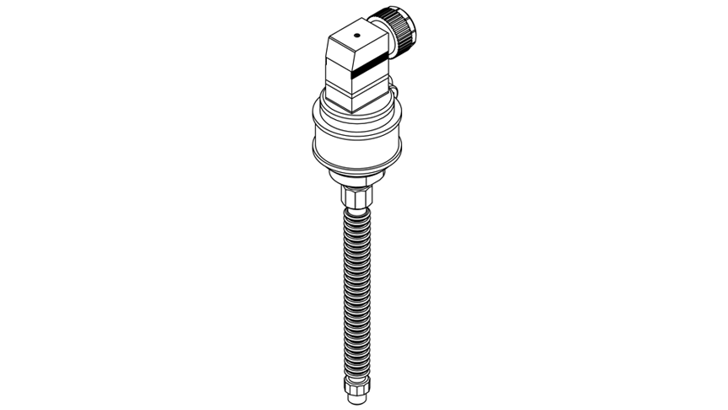

Pressure Sensor

Dr. E. Horn Pressure Transmitter TGL014xxx

The pressure transmitter TGL014xxx from Dr. E. Horn is designed for measuring the absolute and gauge pressure of various liquids including gas and vapors. In general, the pressure sensor from HORN measures the pressure occurring in the engine compartment against the atmosphere. The piston defects can be detected by the means of this pressure measurement; thus, it is an essential variable in the assessment of the smooth operation of your engine.

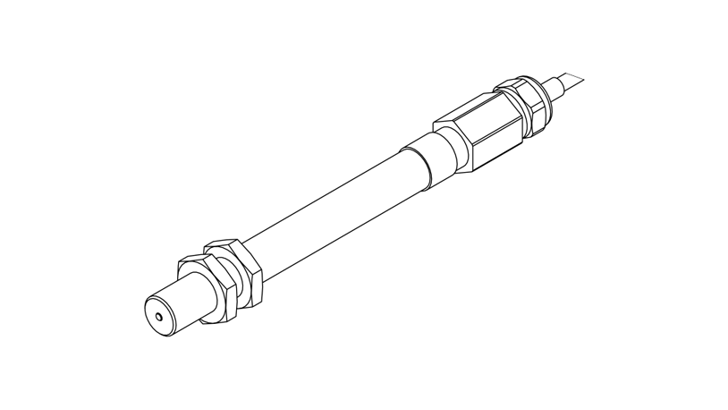

Speed Sensor

Dr. E. Horn Speed Sensor FGL 01620

The speed sensor FGL 01620 from Dr. E. Horn can be used both at extremely low speed, and almost full stop can be detected, and it is also applicable for highspeed rotations up to 20kHz frequency. It is a preferred sensor for offshore and marine purposes because of its vigorous stainless-steel design.

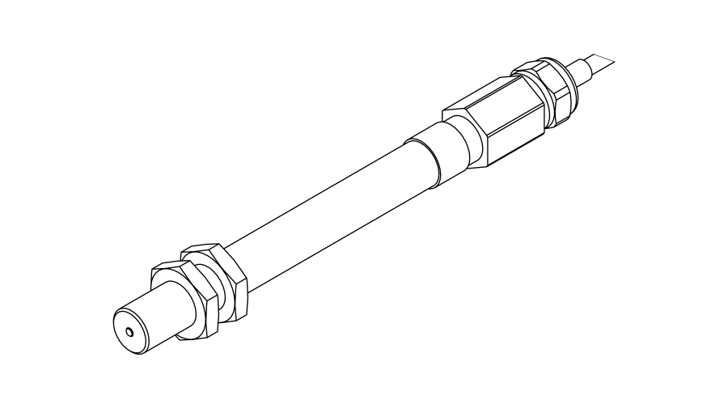

Water in Oil Sensor

Dr. E. Horn Water in Oil (WiO) System FRG00032

The Water in Oil system from Dr. E. Horn consists of a sensor FRG00032, a connection box GHG02088-5, a connection cable KSG03244-1, and three relay outputs. Additionally, to the basic standalone version, is the option to get an analogue output for water content and oil temperature, as well as an indicator box with analog indicator(s), operating devices, and an acoustic alarm.

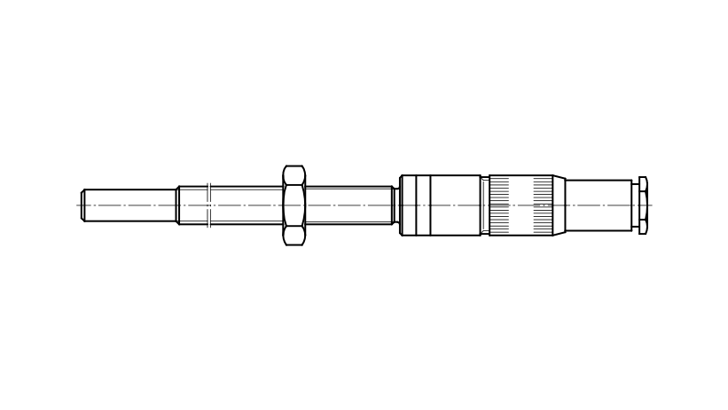

Turbocharger Speed Sensor

Dr. E. Horn Turbocharger Speed Sensor FGL 1/16

The speed sensor FGL 1/16 from Dr. E. Horn is composed of a metallic housing that contains the sensor components and, in some cases, the electronic components. This design ensures mechanical durability and prevents interference from external circuits.

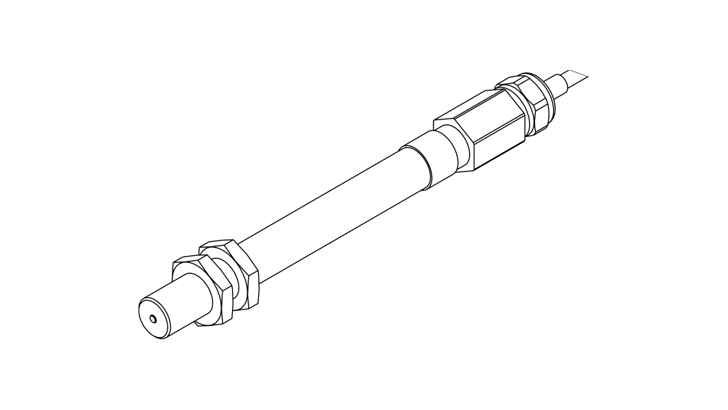

Inductive Pulse Sensor

Dr. E. Horn Speed Sensor FGL 01406

The speed sensor FGL 01406 from Dr. E. Horn is composed of a metallic housing that contains the sensor components and, in some cases, the electronic components. This design ensures mechanical durability and prevents interference from external circuits.

Inductive Phase Sensor

Dr. E. Horn Speed Phase Sensor FGL01364

This FGL 01364 from Dr. E. Horn is an inductive phase sensor with an amplifier, which is ideal for sensing objects such as gear wheels, punched discs, and integral steel shafts. It features a coil with an oscillator circuit and amplifier. By adjusting the air gap between the object and the sensor tip, voltage changes in the coil/oscillator system are detected and evaluated.

No results found

Condition Monitoring

No One Wants a Vessel Taken Unexpectedly Out of Operation. Enter Maintenance!

Breakdowns and malfunctions are never welcomed and can lead to heavy repair costs and loss in earnings, which is why maintenance of equipment is critical. Maintenance schemes and programs have become better over time as focus has shifted from reactionary maintenance towards a more preventive oriented approach.

By avoiding shutting down systems for repairs and planning maintenance work based on experience and calculations, a lot of time and money has been saved, as well as many stressful situations for the crew has been dodged. But, how do you actually know that the preventive maintenance carried out, is not done too excessively and too often, thus actually costing more than necessary? By imple-menting condition monitoring as a concept, you can enable crew and operators to gain an insight in the actual ‘health’ of main and auxiliary systems on board.

What Is ‘Condition Monitoring’?

The term ‘condition monitoring’ covers a very wide array of products that are designed to provide indications about a systems’ operational health. When using condition monitoring, the crew and operators can get actual insight about a particular system’s condition by directly analyzing the system or component.

The condition monitoring equipment will provide you with information about wear, tear and present failures. By carrying out systematic and periodical analysis of your equipment you can prevent unexpected failures and plan your maintenance more wisely, saving time for your crew and money on equipment repairs.

How Does it Work?

As condition monitoring is a definition that includes many different products, it can work in just as many ways. But in general the condition monitoring equipments look for things that are out of the ordinary for example particles in lube oil, contaminants in fuel oil or specific vibrations of engines, shafts and generators.

By continuously monitoring the day to day operation the crew cannot only determine if maintenance is required but also identify the root cause.

The upper section contains a collection of condition monitoring equipment, that can assist in optimizing maintenance efforts, identify and prevent critical failures before they happen and minimize down-time by scheduling optimally. If you are looking for something specific and it is not found here, please contact us and we will see what we can do to help you.