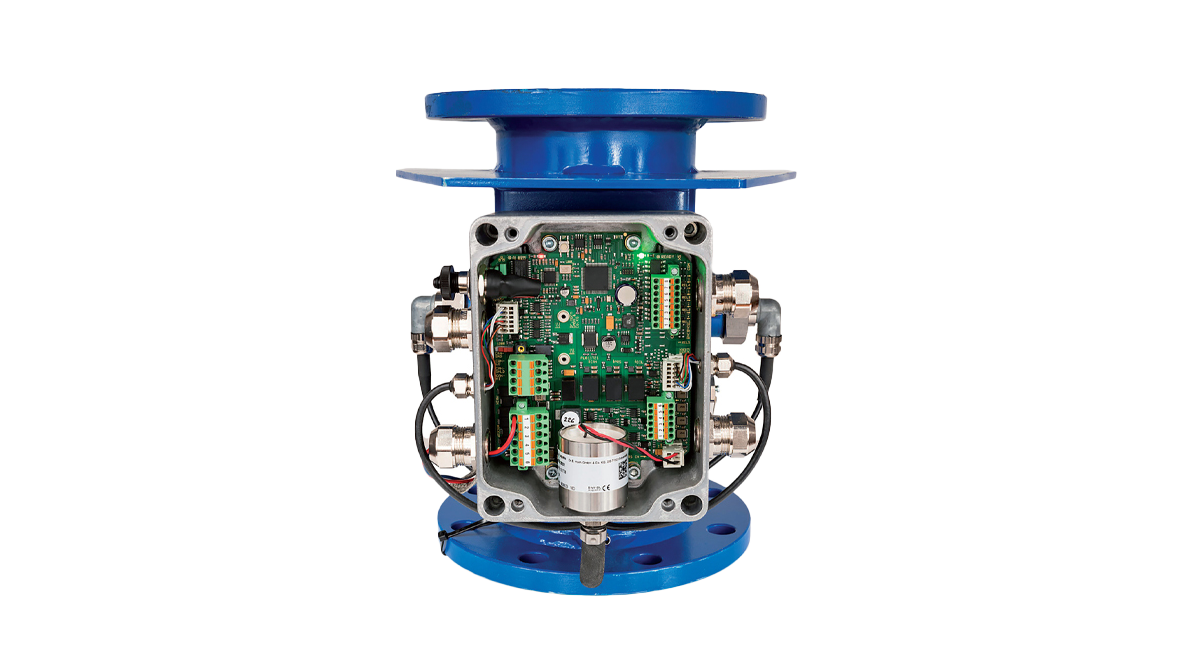

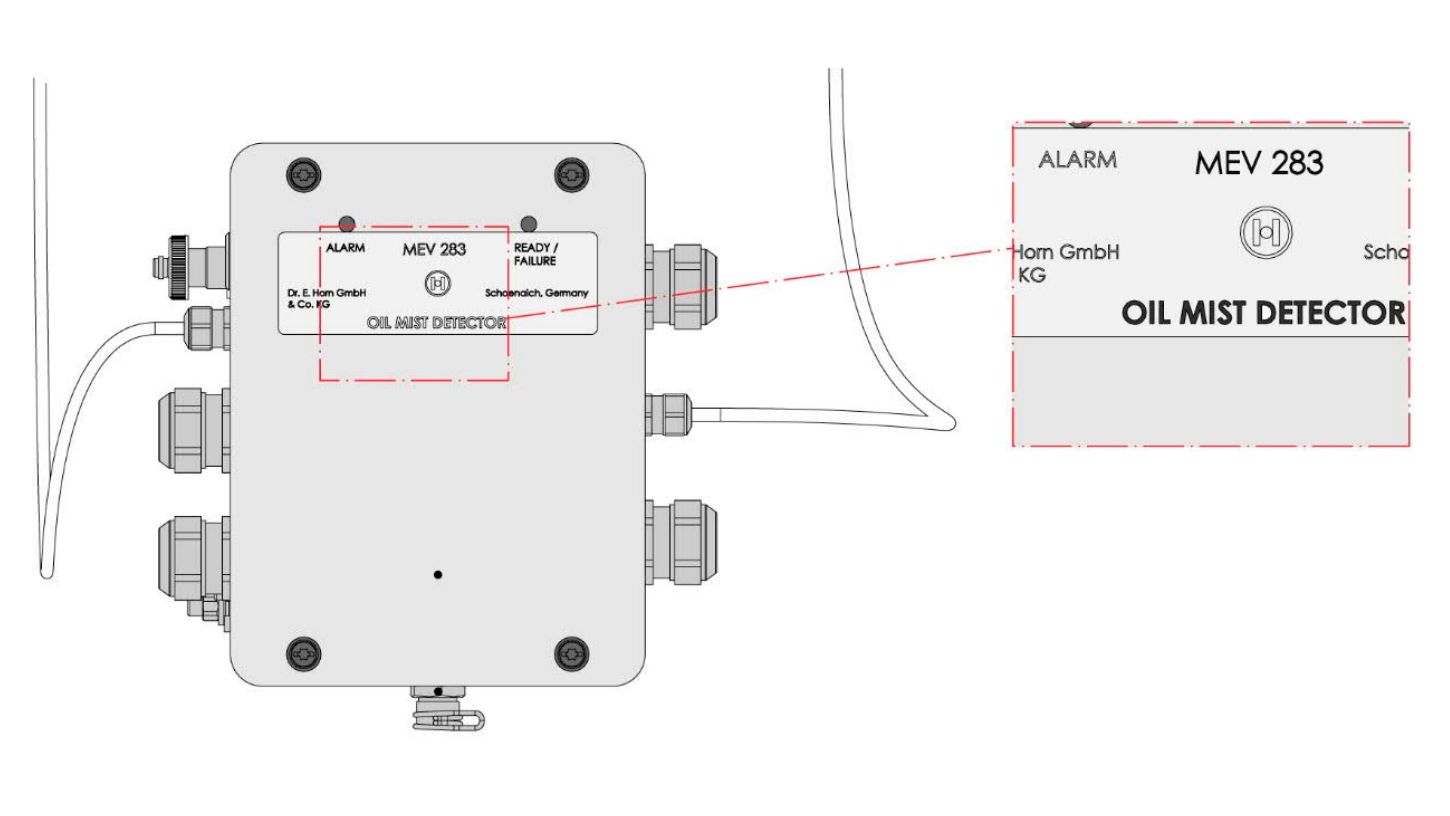

Compact Oil Mist Detector (MEV283)

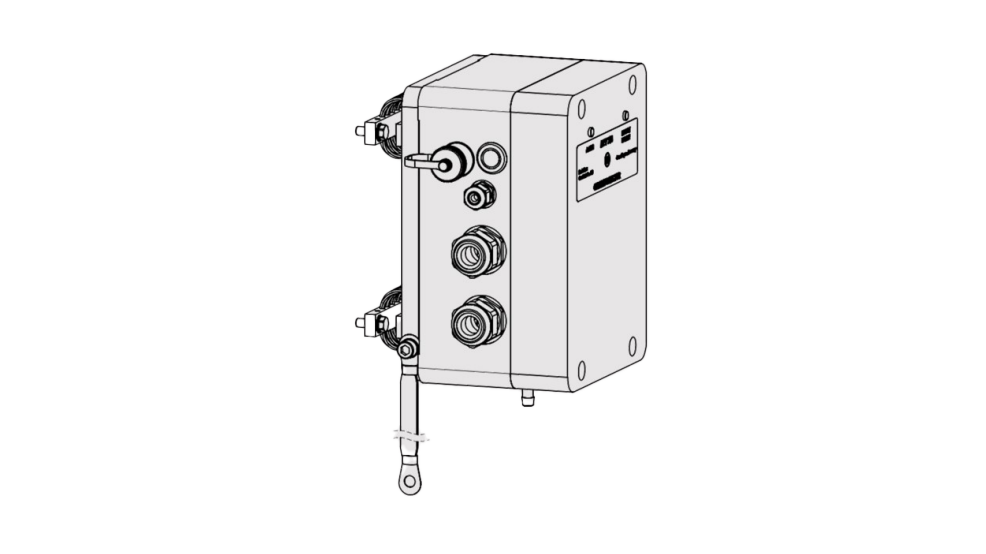

The Dr. E. Horn Oil Mist Detector is a compact system, which can detect even the smallest changes in the oil concentration and is connected to the vessel’s automation security system. Moreover, this system can be retrofitted and mounted directly on the pipes for crankcase ventilation. Thus, no additional pipping is required in the assembly.

This system benefits you because of the:

- Compact unit size

- Long-term usage

- Simple installation on breather outlet, no drilling of the engine required

- No need for artificial suction

- Option to have a crankcase pressure sensor

- Retrofit service available

- Cost-effective solution.

We deliver directly and globally to end-users, agents, and resellers.

Contact us at marine@insatech.com.