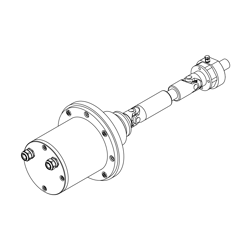

Crank-Case Protection System (CPS)

The Crank-Case Protection System (CPS) from Dr. E. Horn is specifically engineered to monitor the bearings of 4-stroke Diesel engines. By converting a thermoelectric measurement taken between the rotating shaft (e.g., using brushes) and the engine block, a signal known as the CPS signal is generated, which serves the purpose of monitoring the engine's condition.

The CPS has many advantages including but not excluding to:

- Easy assembly

- Installation can be done by the crew

- Simple maintenance.

We deliver directly and globally to end-users, agents, and resellers.

Contact us at marine@insatech.com.